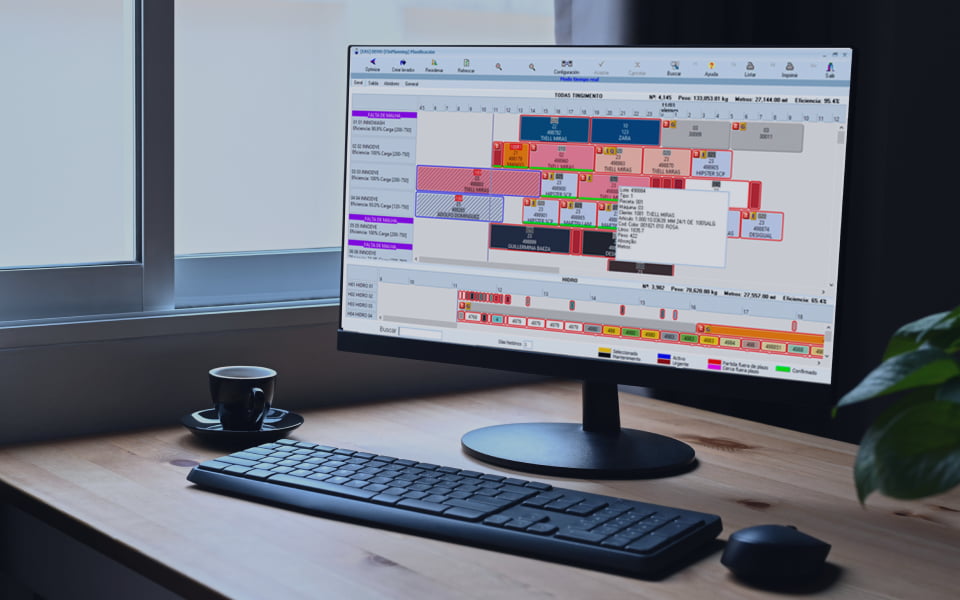

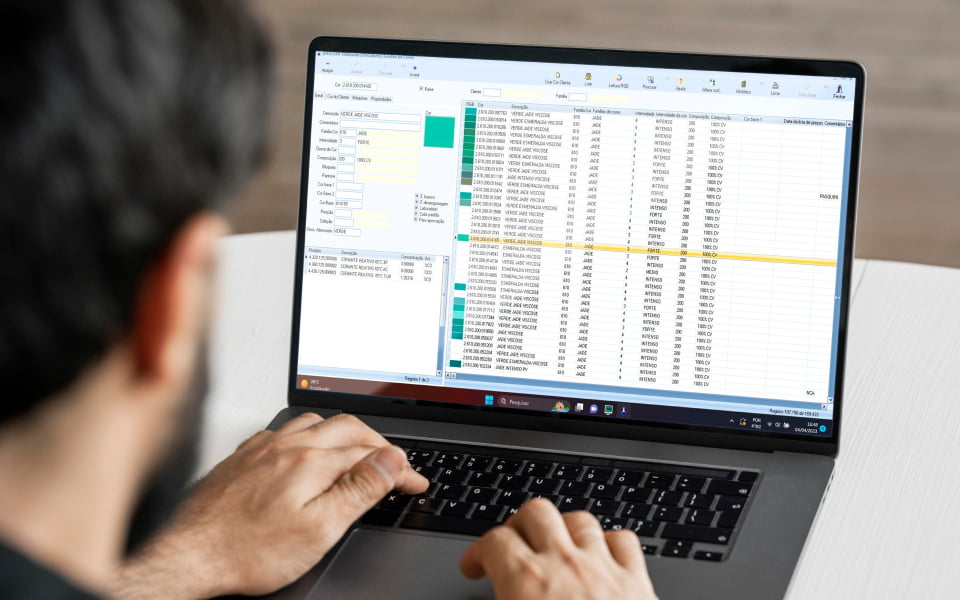

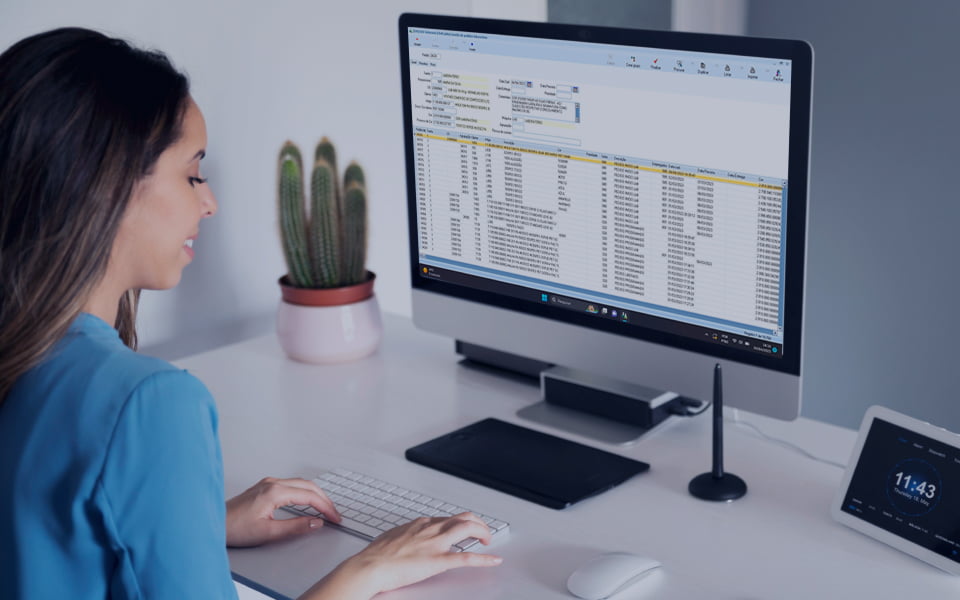

Resource planning in the textile industry is essential to optimize efficiency and profitability. With the increasing demand for textile products, it is crucial to intelligently manage available resources. This includes the management of raw materials, labor, machinery and time. Effective planning ensures smooth production, minimizes costs and reduces lead times. In addition, the implementation of advanced technologies, such as supply chain management software, can further improve resource planning. In a competitive market, strategic planning in the textile industry is the key to sustainable success.