Solutions for denim fabric manufacturing

From our solutions in storage, dosing, and preparation of dyes, we have created an automated working system for the manufacture of denim fabric, focusing on sustainable development for this type of fabric.

Solutions for denim fabric manufacturing

From our solutions in storage, dosing, and preparation of dyes, we have created an automated working system for the manufacture of denim fabric, focusing on sustainable development for this type of fabric.

Innovative technology for textile dyeing and finishing processes

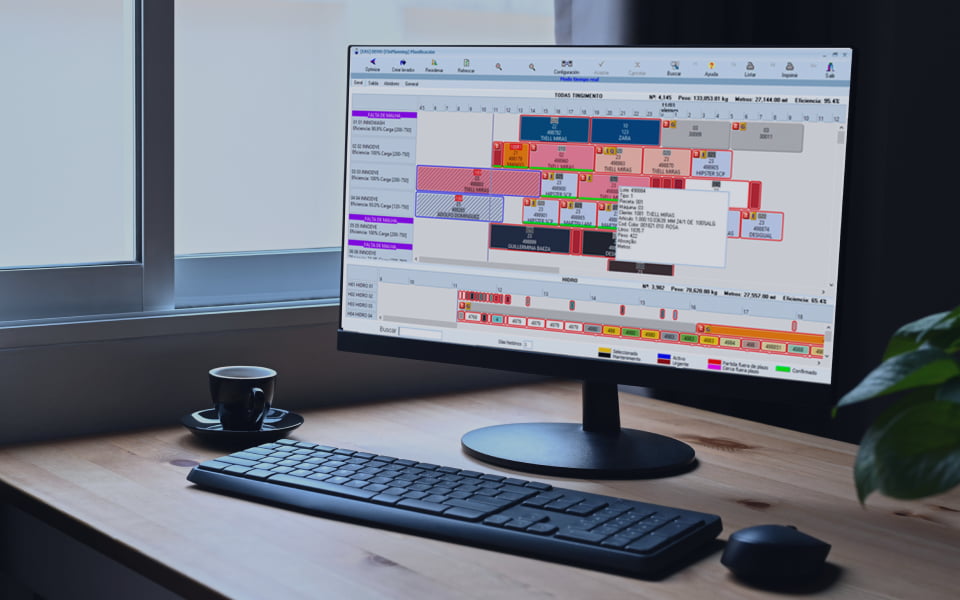

Solution developed by EAS to automate and integrate management of textile dyeing and finishing processes to obtain high quality fabrics.

TecnoDenim is the solution developed by EAS for the integral management of denim fabric manufacturing. A system that allows a complete automation of this process, which contributes to the sustainable manufacturing of this type of fabric.

ERP and MES software for denim fabric manufacture

The manufacturing process starts with the planning and execution of the process using our software calculating all the parameters of the recipe such as fabric gauges, item collection and dye ratio. By digitizing this process, we achieve the accurate delivery of the exact quantities of product.

By combining our dosing systems, we create an automated workflow for denim fabric production companies.

Safe loading and storage of chemicals

TecnoFill is the chemical loading and management system for the textile industry. This system manages the loading of chemicals and auxiliaries by creating an online inventory.

High precision dosing system

TecnoDos is in charge of distributing the different products to the machines automatically. A precise dosing system that helps to reduce the consumption of raw materials while remaining faithful to the process recipe.

Creation of spectacular indigo dyes

TecnoMix prepares the dye mixture following the recipe precisely and sending the mixtures to storage tanks or to the denim dyeing machine section.

The most complete and versatile controller on the market

Atlantis is in charge of controlling the whole process by executing the programmed orders in the different machines and collecting all the essential data for further analysis.

Reliability guaranteed

We have put our more than 30 years of experience in the industry to design durable, high-performance products. Plus, with our remote technical support service, we’ll help you whenever you need it.

We and use cookies and other tracking technologies to improve your experience on our website. We may store and/or access information on a device and process personal data, such as your IP address and browsing data, for personalised advertising and content, advertising and content measurement, audience research and services development. Additionally, we may utilize precise geolocation data and identification through device scanning.

Please note that your consent will be valid across all our subdomains. You can change or withdraw your consent at any time by clicking the “Consent Preferences” button at the bottom of your screen. We respect your choices and are committed to providing you with a transparent and secure browsing experience.

Privacy Overview