Textile ERP Software: The Key to Efficiency in the Industry

In the textile sector, efficiency and planning are vital for success. One of the fundamental pillars to achieve these goals is the implementation of textile ERP software. In this article, …

In the textile sector, efficiency and planning are vital for success. One of the fundamental pillars to achieve these goals is the implementation of textile ERP software. In this article, we will explore in detail how these specialized systems can revolutionize business management in the textile industry. From the definition and features of ERPs to their specific application in the textile industry, we will unveil why they are the essential tool for any company seeking to remain competitive in an ever-changing market.

What are ERP Software?

Enterprise Resource Planning (ERP) systems, known as ERP, are the backbone of modern business management. These programs allow the unification and organization of all areas of a company into a single integrated system. But how can they benefit the textile industry? Let’s delve into the details.

La Importancia de la Unificación y

The Importance of Unification and Traceability

In the textile business landscape, where production, logistics, inventory, and other processes are closely interconnected, unification and traceability are essential. ERPs enable all these elements to be connected and synchronized within a single system, providing a comprehensive view of the company.

Optimizing Business Processes

Optimization is the key to staying competitive in the textile market. ERPs not only facilitate process automation but also identify areas for improvement. This allows companies to streamline their operations, reduce costs, and increase efficiency across the production chain.

Efficient Resource Planning

In the textile industry, where orders can vary in size and complexity, efficient resource planning is essential. ERPs allow for precise production planning, helping companies meet delivery deadlines and effectively manage available resources.

Automation and Interdepartmental Connectivity

Automation is a crucial component of ERPs. These systems enable the automation of repetitive tasks and seamless connectivity between different areas of the company, from production to accounting. This not only saves time but also minimizes human errors.

Access to Data and Structured Information Creation

Information is power in the textile industry. ERPs collect and structure data coherently, providing valuable insights for decision-making. This facilitates trend identification, inventory management, and supply chain optimization.

Sharing Information

ERP systems enable real-time information sharing among all departments of the organization. This promotes more effective communication and closer collaboration between teams, resulting in greater operational efficiency.

Key Features of ERPs

ERPs are distinguished by being modular, configurable, and specialized:

Modular: ERPs are designed to understand that a company is a set of interconnected departments. This is reflected in their modular structure, allowing companies to select and implement only the modules they need to fit their specific processes.

Configurable: Configuration is essential in adapting an ERP to the needs of a textile company. Advanced ERPs offer programming tools that allow customization of the software to address specific requirements, such as batch inventory control.

Specialized: A generic ERP may offer generic solutions, but for textile companies facing unique challenges, having a specialized ERP is crucial. These systems adapt to the specific needs of the industry, providing effective solutions.

Other Considerations in the Textile Industry

The textile industry presents additional challenges that make ERP implementation even more crucial:

Complexity Management: In the textile industry, various departments, from laboratories to specific production areas, must interact efficiently. ERPs help manage this complexity by providing an overview of operations.

Pressure for Quick Production: Orders in the textile industry are increasingly smaller and require faster deliveries. An ERP enables precise planning and agile management to meet these demands.

Complex Workflows: Textile production processes often involve multiple steps and machines. ERPs ensure that these workflows are rigorously followed to produce high-quality products.

Need for Reworking: Occasionally, fabrics need to be reprocessed to ensure they meet technical specifications. ERPs help track and efficiently manage these processes.

The Challenge of Customization

Implementing an ERP in the textile industry can be a challenge due to the need for customization. However, this customization should not come at the expense of time and money. Finding a balance that allows the company to make the most of ERP capabilities without incurring excessive costs is crucial.

How to Implement an ERP Correctly

For a successful ERP implementation in the textile industry, the following fundamental aspects must be considered:

Selecting a Specialized ERP: Opting for an ERP designed specifically for the textile industry reduces the need for costly customizations.

Informed Technical Team: The team responsible for implementation should understand the unique challenges of the company and define an effective implementation strategy.

Specific Methodology: Each sector of the textile industry has its peculiarities. Working with a methodology tailored to these needs is essential.

Efficient Project Management: Strong project management is crucial to ensuring a seamless implementation.

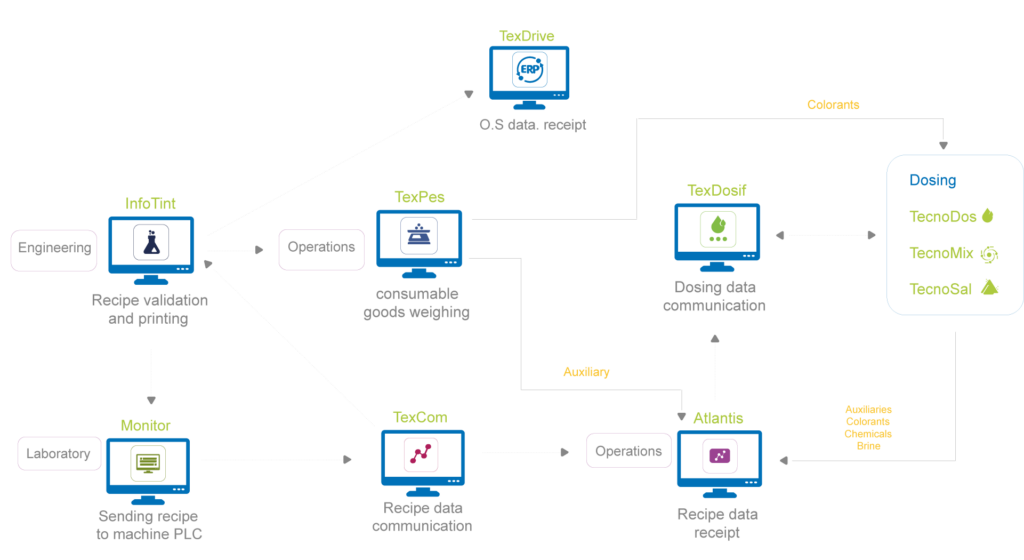

TexDrive: EAS’s ERP for Textile Business Management

TexDrive is the ultimate textile management solution designed to provide complete control over your plant’s operations. We offer comprehensive integration of the entire production cycle, from generating production orders to the final stage of finished products, including all intermediate processes, including route sheet preparation.

The Importance of Continuous Training

Digital transformation and ERP adoption are fundamental steps for the textile industry in the era of Industry 4.0. However, continuous training is essential to keep the system up-to-date and ensure its proper management.

Implementing an ERP in the textile industry is a strategic investment that can boost efficiency, quality, and competitiveness. The benefits of unification, optimization, and process automation are invaluable in such a dynamic market. If you want more information on how an ERP can transform your textile company, please do not hesitate to contact us. We are here to help you take the next step towards excellence in textile business management.