Practical guide for optimizing production in textile factory

Have you ever wondered how to make your textile factory run better? We know that in this business, efficiency is essential, and in this article, we bring you some practical …

Have you ever wondered how to make your textile factory run better? We know that in this business, efficiency is essential, and in this article, we bring you some practical tips that can truly make a difference. Whether you have a lot of experience in the industry or are just starting out, these tips will be useful for improving your textile factory and increasing production.

Organization as a Key Factor

Organization plays a fundamental role in improving production in your textile factory. Maintaining a clean and well-organized environment makes it easier for workers to find what they need quickly and efficiently, while reducing downtime and potential errors. Consider investing in effective storage systems and establish a clear and effective workflow as part of your strategy.

Technology and Automation

Process automation is a strategy that can have a significant impact on the efficiency of your operations. Incorporating advanced machinery or automating existing ones reduces production times and minimizes human errors.

But technology is not limited to production alone. It can also improve overall factory management, from workforce scheduling to order tracking and supply chain management. Implementing a suitable Enterprise Resource Planning (ERP) system can facilitate the coordination of all these aspects and optimize your operations overall.

Employee Training

Having a well-trained team is essential. Ensure that you provide your employees with the training they need and keep their knowledge up to date with the latest techniques and technologies in the textile industry. A competent team is not only more productive but also reduces the likelihood of costly errors. Additionally, don’t forget to promote business policies that create a positive work environment. A friendly and collaborative work environment not only motivates employees but also contributes to optimal performance and efficient workflow. The combination of a well-prepared team and a healthy work environment is the key to sustainable success in the textile industry.

Smart inventory management

I recommend using inventory management systems that allow you to have real-time control over the quantity of raw materials and finished products in your factory. This way, you can avoid uncomfortable situations like running out of materials or having excess inventory.

Maintaining the right inventory is like having a well-stocked pantry at home. Imagine having everything you need to cook your favorite meals while also having enough space to store fresh food you regularly buy. This allows you to always have what you need on hand, without wasting or running out of anything.

The same applies to your factory. With an efficient inventory management system, you can know exactly how many raw materials you have available and how many finished products are ready to be shipped. This helps you plan your orders better, avoiding production delays due to material shortages. Additionally, it also helps you avoid excess inventory, which can lead to unnecessary costs and occupy space that could be used for other purposes.

Rigorous Quality Control

Quality is absolutely essential in textile production. To ensure high-quality products, it is essential to implement rigorous quality control at every stage of the manufacturing process. This involves conducting thorough inspections to identify any possible defects or imperfections in textile products. By doing so, problems can be detected and corrected before the products reach the hands of customers.

Having a strong and effective quality control system significantly reduces the number of defective products that leave the production line. This not only has a positive impact on the company’s reputation but also helps avoid costly claims and returns from dissatisfied customers. Furthermore, by offering high-quality products, customer satisfaction is increased, which can lead to loyalty and repeat purchases.

Preventive Maintenance

Keeping your machines and equipment in excellent condition is essential to ensure they function perfectly and avoid costly complications down the line. Here are some practical tips for establishing a preventive maintenance program that not only keeps your machinery in optimal condition but also safeguards your investment:

- Constant Inspection: Regularly inspect your machines and equipment to detect any signs of wear, damage, or potential issues. Pay special attention to critical components and ensure they are in good condition.

- Cleaning and Lubrication: Schedule routine cleaning sessions to remove dust, dirt, and other residues that could affect the performance of your machines. Additionally, follow the manufacturer’s guidelines for proper lubrication of moving parts.

- Replacement of Worn Parts: If you notice any worn parts during your inspections, replace them promptly. Don’t let them reach the point of complete failure, as this could lead to additional damage and downtime.

- Precise Calibration and Adjustments: Regularly verify the calibration and adjustments of your equipment to ensure they operate within the correct parameters. This is crucial for avoiding accuracy and performance issues.

- Detailed Record-Keeping: Maintain a comprehensive record of all maintenance tasks performed, including dates, activities carried out, and any problems encountered. This allows for efficient tracking of maintenance efforts and more accurate planning for future interventions.

Remember that preventive maintenance is the key to avoiding unexpected expenses and long periods of downtime. By establishing an appropriate maintenance program and following these guidelines, you will not only extend the lifespan of your machines and equipment but also maximize their performance and minimize repair costs. If you want more information on textile machine maintenance, we invite you to visit our blog, where you can find a detailed article on the topic.

Practice continuous improvement

You should never stop looking for ways to advance and improve. Cultivating a culture of continuous improvement is crucial, with special attention to your employees’ suggestions, as they can provide valuable ideas for optimizing our processes. Additionally, incorporating innovative technologies, conducting in-depth reviews of our work methods, and relentlessly seeking more effective solutions are highly recommended practices. Remember that this is an ongoing process that never stops. By constantly searching for ways to improve, you can ensure that your textile factory remains competitive and successfully adapts to the changing market demands.

The importance of sustainability

Embracing sustainable practices in our factory is essential to stay ahead in this important trend. One way to achieve this is by using recycled materials instead of always relying on new raw materials. This not only has a positive impact on reducing the amount of waste we generate but also plays a vital role in preserving our precious natural resources.

It is crucial that we work together to reduce waste generation at every stage of our manufacturing process. This means taking concrete steps to minimize material waste and optimize the responsible use of essential resources such as water and energy. By doing so, we not only contribute to the well-being of our environment but could also reap long-term economic benefits by saving on operational costs.

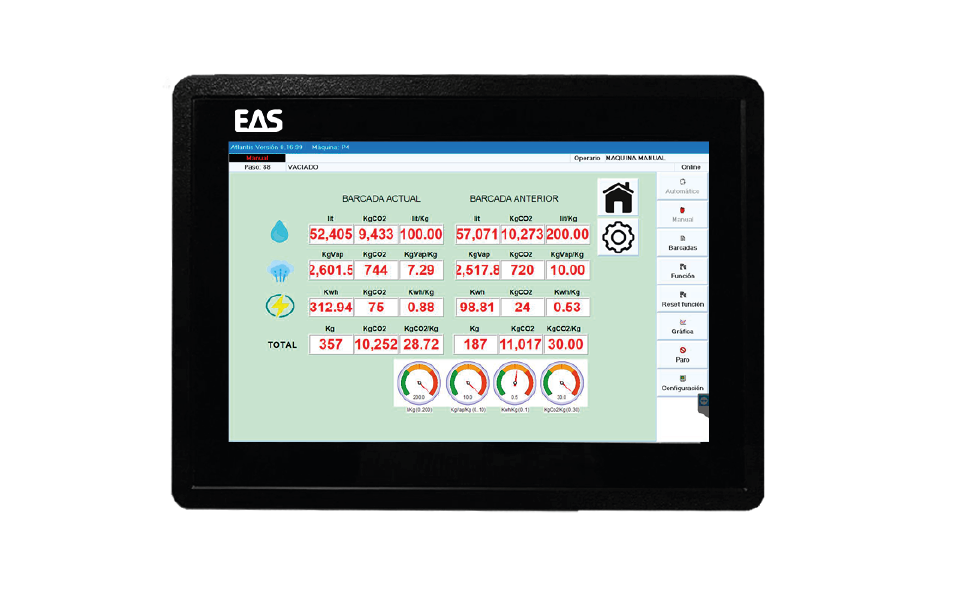

One example is our Atlantis controller and its consumption screen. It provides a valuable consumption screen, an essential tool that revolutionizes the way you manage your industrial resources. This innovative functionality not only boosts the efficiency of your processes but also promotes sustainability. Through Atlantis, you will have the ability to maintain constant and precise control over your machine’s consumption, representing a crucial step in your pursuit of operational efficiency and your commitment to environmental responsibility.

Conclusion

Optimizing production in your textile factory is not a one-time process but a continuous effort. In this context, we have prepared a table that summarizes the key aspects and fundamental strategies for enhancing efficiency and productivity in this ever-evolving industry.

| Aspect | Strategy | Description |

|---|---|---|

| Inventory Management | Implement a JIT (Just in Time) system | Reduce storage costs and minimize waste by producing only what is needed when it is needed. |

| Production Processes | Automation | Incorporate modern machinery and automated systems to speed up production and reduce errors. |

| Production Planning | MRP (Material Requirements Planning) System | Use an MRP system to efficiently schedule production based on demand and inventory levels. |

| Quality Management | Implement a quality control system | Conduct regular inspections to ensure product quality and reduce rework. |

| Employee Training | Continuous training | Provide ongoing training and development for employees to enhance their skills and knowledge. |

| Energy Efficiency | Use energy-efficient technologies | Adopt technologies and practices that reduce energy consumption and associated costs. |

| Order Management | Integrated order management system | Utilize a centralized system to manage orders, reducing errors and delivery delays. |

| Preventive Maintenance | Regular maintenance program | Perform preventive maintenance on machinery and equipment to prevent unplanned downtime. |

| Cost Management | Cost analysis and reduction of unnecessary expenses | Identify high-cost areas and seek ways to reduce them without compromising quality. |

| Research and Development | Development of new products | Invest in creating new or improving existing products to maintain competitiveness. |

Organization, technology, employee training, and other factors play a crucial role in the success of your business.

Implement these tips and watch as your textile factory reaches new levels of efficiency! If you need assistance in any of these areas, contact us, and we will conduct a personalized assessment of how we can assist you.