We optimize textile production by integrating recipes from the lab, quality control and color development. Our strategy reduces errors and helps you save on implementation costs.

Textile Software

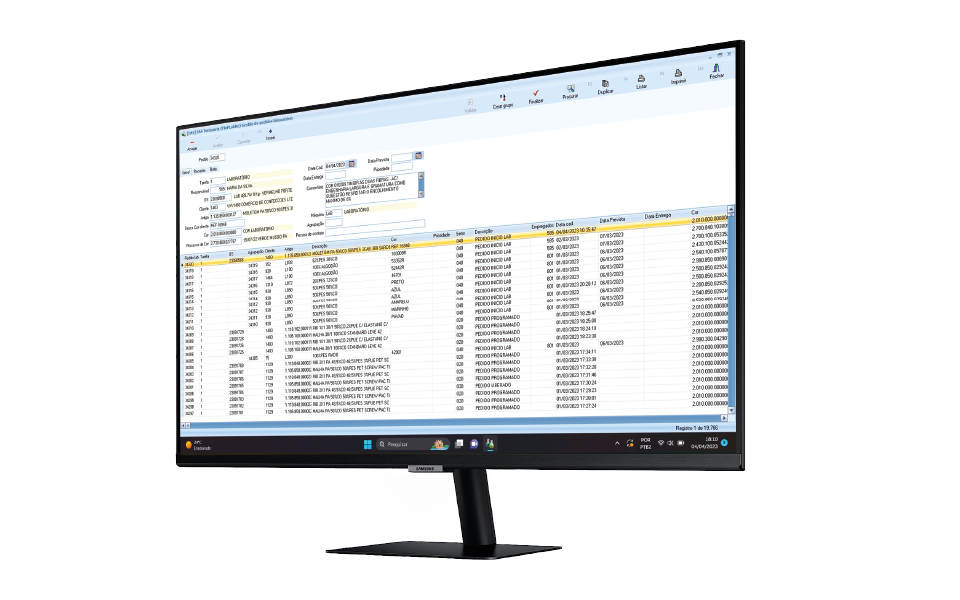

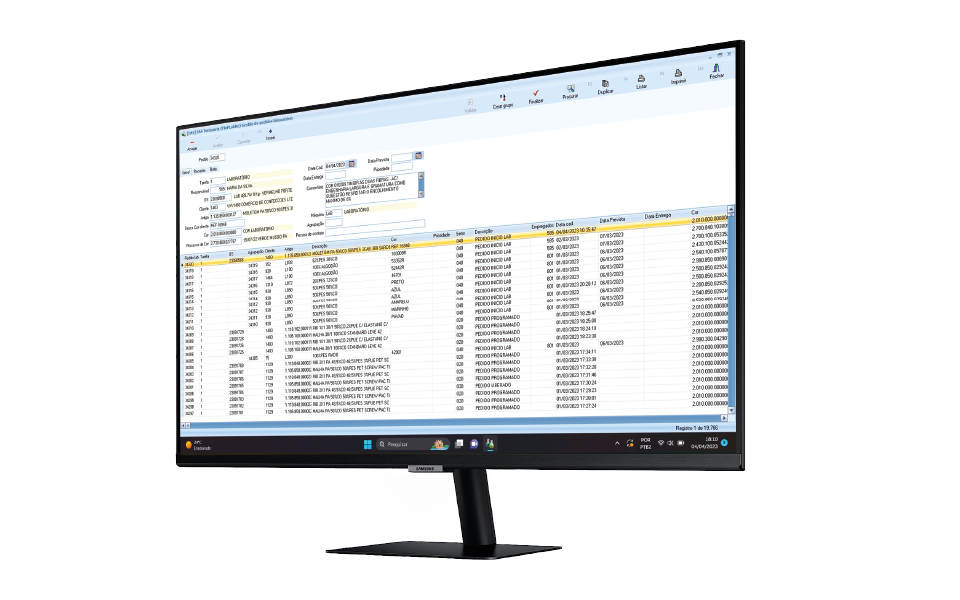

Software for laboratory recipe management, quality control and color development in textile manufacturing.

TexLab integration with quality and R&D laboratory

TexLab is the essential InfoTint module for the integration and implementation of recipes from the laboratory, quality control and color development ensuring production aligned with development specifications.

- Gain more control over production.

- Simplify process management.

- Optimize decision making.

- Embark on the road to digital transformation of your business.

Ensure quality, eliminate errors, and simplify tasks. You can reduce costs and gain competitiveness. Give your growing company a new impetus for success.

Functionalities

The TexLab module emerged with the objective of organizing laboratory orders. However, it has become a strategic software for integrating laboratory recipes with production, avoiding recipe standardization problems, as well as integrating production quality control based on color development in the laboratory.

Why TexLab?

TexLab is a management software designed to speed up production times while reducing human error.

Integrate the laboratory and the R&D control center now and boost your production

Boost your production by integrating your laboratory and R&D control center. The key to success is to unify your resources – discover a new level of efficiency today!

- Automatic request of development orders from PCP

- Integration of the laboratory recipe with the production recipe

- Integration with TexOffer module for cost control, price formation and quotation generation

- Order control by priority

- Possibility to indicate the appropriate recipe according to rules (intelligent recipe)

- Integration with spectrophotometer for reading of color properties

- Order status control

- Automatic recording of color code and intensity