Success Story: Fakini Accelerates Its Journey Toward Industry 4.0 with EAS

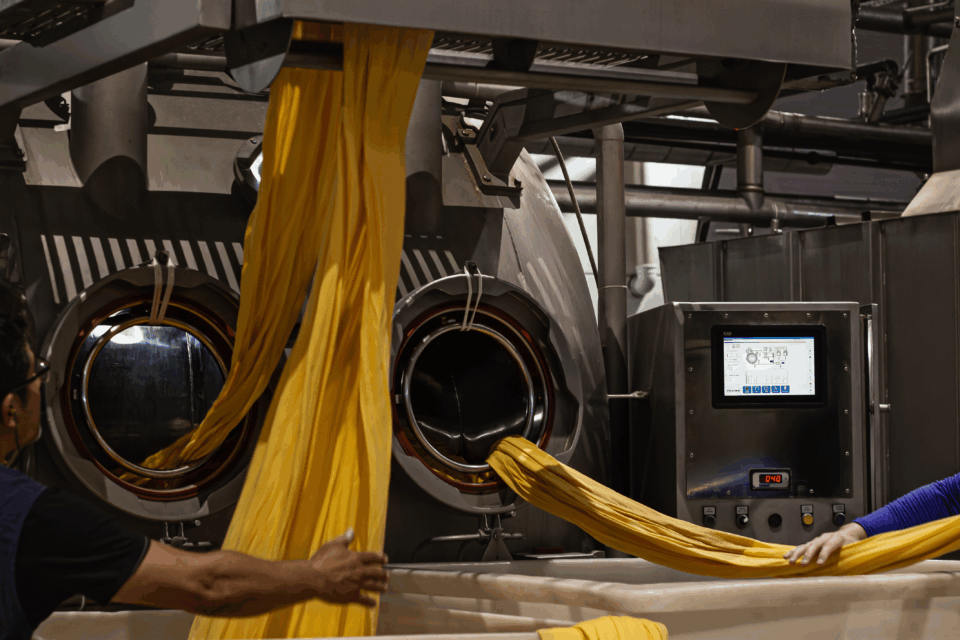

In the competitive textile market, innovation is no longer an option — it’s a necessity. With this mindset, Fakini decided to make a major investment in modernizing its dye house. …

In the competitive textile market, innovation is no longer an option — it’s a necessity. With this mindset, Fakini decided to make a major investment in modernizing its dye house. The challenge was significant: transforming traditional, often manual processes into fully automated, precise, and connected operations. To achieve this technological leap, the company chose EAS as its strategic partner — and the result was a true revolution toward Industry 4.0.

The Challenge: Boosting Productivity and Quality Through Automation

Fakini’s factory, a national reference in children’s clothing production, faced challenges that affected its competitiveness:

- Manual processes that were time-consuming and prone to errors.

- Wasted time and chemicals due to manual weighing of auxiliary products.

- Production times that showed room for efficiency improvements.

These bottlenecks reduced efficiency and limited operational flexibility, creating a scenario that demanded change.

The EAS Solution: Cutting-Edge Technology and Integration

After a thorough assessment, EAS proposed a complete automation solution that combined advanced technology, connectivity, and practicality. The modernization included:

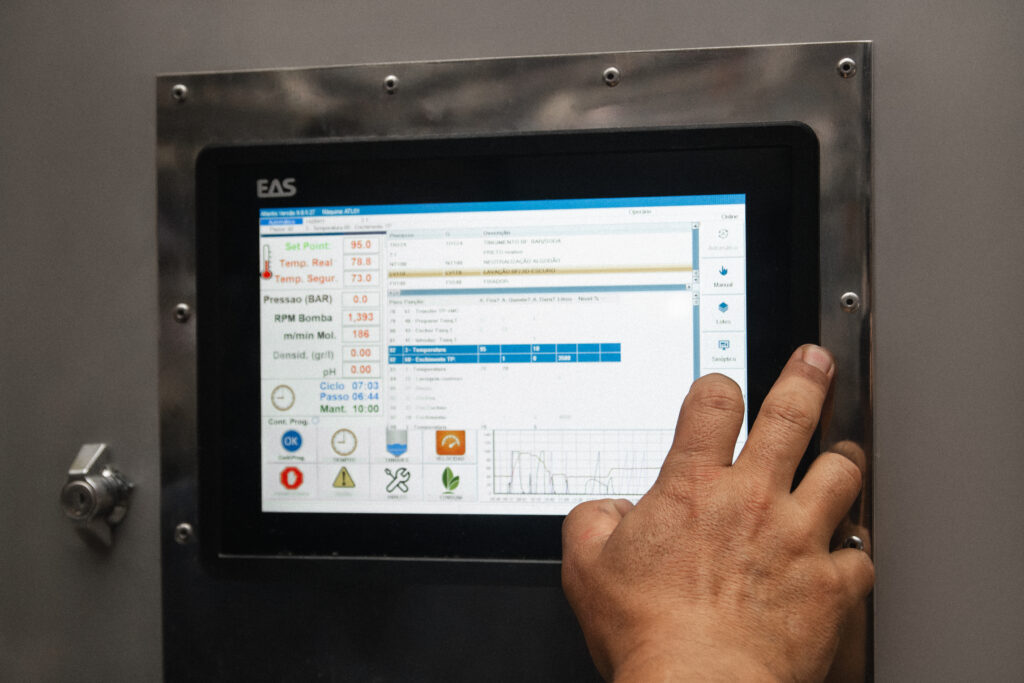

- PCT310 Machine Controller: Implemented across the renovated fleet of machines, it provided customized automation tailored to Fakini’s needs. The result: higher precision, reduced variability, and much faster processes.

- MES InfoTint System: The heart of the digital transformation. All dyeing and finishing recipes are now centrally managed and digitized, enabling real-time monitoring, full traceability, and standardized production.

- TexPes Weighing Control: The dye scales were connected to the system, ensuring accurate dosing and automatic inventory control. This minimized human error, reduced rework, and optimized raw material usage.

- TecnoDos – Automatic Chemical Dosing System: A true game changer. TecnoDos took over the dosing and transfer of liquid products directly to the machines, eliminating manual tasks, reducing waste, and creating a cleaner, safer, and more ergonomic work environment.

Results: Efficiency, Quality, and Sustainability at a New Level

The benefits for Fakini were immediate and transformative:

- Operational Efficiency

- Automation significantly reduced setup times, sped up production cycles, and increased productivity without compromising quality.

- Consistent Quality

- Standardized recipes and precise dosing improved reproducibility, reduced variability, and ensured excellence in every production batch.

- Sustainability and Cost Reduction

- Lower material waste and smarter resource use directly reduced costs and improved the sustainability of operations.

- Real-Time Management

- Integration between MES InfoTint and TecnoDos provided complete visibility and control over production, enabling faster decision-making and boosting Fakini’s competitiveness.

- Safety and Ergonomics

- The elimination of manual operations and a cleaner, more organized workspace improved working conditions and employee safety.

A Model for the Textile Industry

Today, Fakini stands as a benchmark in the practical implementation of Industry 4.0 in the textile sector. The company successfully combined innovation, efficiency, and sustainability in a production model that strengthens its market position and inspires other factories to follow the same path.

If Fakini’s story inspires you, know that the EAS team is ready to help your company transform its dye house and achieve similar — or even greater — results.

The future of textile production is already here, and we can take you there