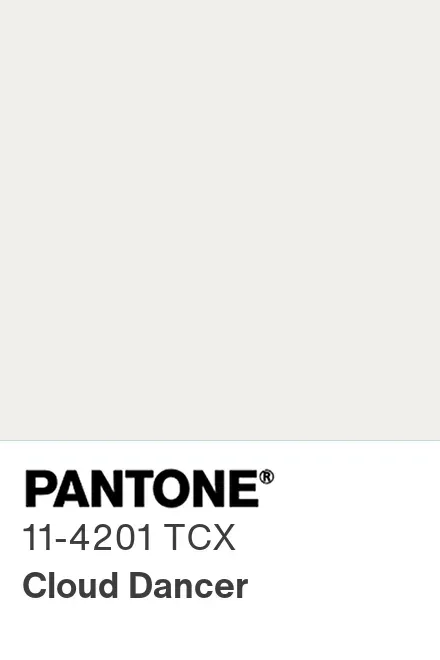

Pantone® Chooses Cloud Dancer as the 2026 Color of the Year: A White Shade Making a Global Trend Statement. What Does It Mean for the Textile Industry?

This year, Pantone has taken an unexpected turn by announcing, for the first time ever, a white as the Color of the Year: PANTONE 11-4201 Cloud Dancer. And it’s not …

This year, Pantone has taken an unexpected turn by announcing, for the first time ever, a white as the Color of the Year: PANTONE 11-4201 Cloud Dancer. And it’s not just any white; it’s described as an “airy, ethereal shade with a soft, calm presence.” In other words, a color meant to evoke serenity, mental clarity, and the feeling of starting from a “blank canvas” in a world increasingly saturated with visual stimuli.

According to the Pantone Color Institute, Cloud Dancer aims to serve as a bridge toward a kind of visual and emotional pause. The idea is straightforward: simplify, slow down, and create space for a more functional creative renewal. And, as is often the case with the Color of the Year, its impact reaches far beyond aesthetics.

In fashion, décor, and interior design, this white is already emerging as a symbol of contemporary minimalism, purity, and chromatic versatility. But the real question is: what does it actually mean for the textile industry?

1. A palette shift with real consequences

When a color becomes a global trend, demand for that shade multiplies. And in this case, it’s not just about a “pure” white, but the entire family of whites, ecrus, and off-white tones.

Brands currently designing their 2026–2027 collections have already begun adjusting their palettes. This will translate into increased orders for white fabrics, higher stock requirements, greater purchases of fibers, chemicals, and bleaching agents, and above all, a heightened demand for consistency.

Those who anticipate the shift will be able to secure major contracts or guarantee large production volumes. And it doesn’t end with fashion: home textiles, hospitality, and interior décor also rely heavily on neutral fabrics, which further expands the potential market.

2. White: a simple color… until it comes to production

A nivel técnico, el blanco es uno de los colores más complejos de trabajar. Puede parecer contradictorio, pTechnically, white is one of the most challenging colors to work with. It may seem contradictory, but even a slight variation can give the final shade grayish, yellowish, or bluish undertones. And in industrial-scale production, such deviations are critical.

The main challenges are:

- Raw material variability: Different fibers react differently. Change the batch, and the white changes.

- Highly sensitive processes: pH, temperature, timing, chemical concentrations… any fluctuation alters the outcome.

- Growing orders under pressure: When the market demands more white, there’s less room for error and a higher risk of returns.

For this reason, this color trend demands stable processes and precise data.

Automation: the key to riding the Cloud Dancer wave

For a company working with textile automation—whether in dosing, dyeing, finishing, or plant management—Cloud Dancer can become a concrete competitive advantage. It’s not just about following trends: it’s about showing that your plant can reproduce a white shade with surgical precision.

Ability to adapt to demand spikes

When a trend drives up orders, an automated plant can increase output without compromising quality or generating more waste.

Automatic dosing of dyes and chemicals

By eliminating human variability, recipes are executed with exact accuracy. This is crucial when any deviation affects the final shade.

Control of critical parameters

Automation keeps temperature, pH, timing, and flow rates constant. The result: fewer stains, fewer “dirty” tones, and more consistency between batches.

Laboratory-to-plant integration

If a recipe works in the lab, it must perform the same in production. Integrating both environments ensures reproducibility and builds customer confidence.

Full traceability

MES/ERP systems allow documentation of every batch, every parameter, and every incident. In contract or institutional sectors, this transparency is a strong selling point.

How to prepare to take advantage of the trend

If you want to position yourself as a reliable supplier during the Cloud Dancer craze, these steps are essential:

- Communicate your readiness: Demonstrating technical capability and consistency can open doors with demanding brands and buyers.

- Review current capacity: Know how much white you can produce today and how much you could handle if large orders arrive.

- Run pilot tests by fiber: Cotton, polyester, blends, technical fibers… each requires specific adjustments.

- Strengthen quality controls: Measure reflectance, ensure batch-to-batch consistency, and keep thorough process records.

- Plan supplies in advance: Your suppliers will also experience demand peaks. Those who act early will have the advantage.

What happens if this shift isn’t taken seriously?

There are clear risks:

- Loss of opportunities if clients turn to more reliable suppliers.

- Higher likelihood of unstable shades in manual or semi-manual plants.

- Delays due to shortages of chemicals or bleaching agents.

- Increased waste and rework if demand suddenly spikes.

Beyond White: What Cloud Dancer Really Reveals

This color doesn’t succeed solely because of its aesthetics. It’s a sign of something deeper:

- A market seeking calm and simplicity.

- Consumers who value neutrality and versatility.

- A return to minimalism as a design foundation.

- A preference for lasting, essential colors that are easy to integrate.

For the textile industry, this means that value is no longer just about following flashy trends—it lies in mastering the production of flawless basics. And that’s where automated processes make a real difference.

Cloud Dancer: An Aesthetic Trend with Industrial Impact

PANTONE 11-4201 Cloud Dancer is not just a pretty white. It’s a strategic signal. It represents an opportunity for textile companies with advanced technology to showcase their ability to produce with precision, consistency, and efficiency.

The underlying message is clear: if your plant can produce perfect whites, it can produce almost anything. Pantone’s 2026 Color of the Year embodies calm and clarity. In the industrial world, that translates into control, repeatability, and operational excellence—a space where automation isn’t just an advantage; it becomes essential.

If you need guidance on automating your plant and quickly implementing new trends into your production, we’re here to help