Textile software: control all the production of your current company

Life moves very fast on these days. Our lifestyle has changed, and now the customer rewards speed and immediacy while maintaining the quality. For companies this is a challenge as …

Life moves very fast on these days. Our lifestyle has changed, and now the customer rewards speed and immediacy while maintaining the quality. For companies this is a challenge as they must adapt the way they used to work and create new workflows to meet new customer needs.

This challenge involves the necessary automation of the industrial manufacturing processes, where the integration of textile control software is extremely important.

Fast Fashion and the textile industry

With the appearance of the Fast Fashion phenomenon in the industry, textile companies are struggling with short delivery timeframes and large volumes of production in order to be ready in the store, or through e-commerce, as quickly as possible.

Generally, companies who have adapted or even created new working methods have chosen technology focusing on the client as the main target.

Courier companies and food delivery services among others, have opened their market to Internet and apps to provide their services in record-time.

For example: when we place an order to a company like Amazon, a whole supply chain infrastructure is unleashed, ensuring the package reaches customer’s home in a very short time. From the moment the goods arrive at the company’s facilities until the delivery service hands over the package to the customer, a series of processes that must be measured to the millimeter come into play.

The big question is, how can this be achieved? The answer is simple: optimizing all available resources to squeeze them to the maximum while keeping them under control at the same time. The good use of this resources has a positive impact on customer satisfaction.

Companies must invest in technology to adapt their plants, and today that means having good management software as a basis. This allows the entrepreneur to manage the company at all levels, in a traceable way avoiding duplication.

Nowadays it’s easy to come across terms as ERP and CRM. They are acronyms that can cause confusion to the employer who wants to make the leap to this new technology.

While an ERP (Enterprise Resources Planning) system is the software designed to plan all internal tasks of the company such as payroll management, stock of raw materials, supplies, accounting and others; the CRM (Customer Relationship Management) is designed to manage the entire relationship, business opportunities, and management of the customer portfolio.

IT solutions for textile companies

To start optimizing out manufacturing process we need to find an ERP software based on the company needs. For textile industry it would be for example, the management of the raw material warehouse, colour laboratory, control of manufacturing orders, production process and finished product warehouse amongst others. All the key processes involved must be defined in order to ensure the software we chose can manage all of them.

For a textile company this implementation is a big step forward. By controlling in detail all processes we will achieve a production adapted and optimised to fulfill deadlines set by client. Also, it will save costs as we can control in detail the raw materials used, creating an adjusted and measured internal production. All together will impact positively in the quality of the final product.

TexDrive the solution for textile production

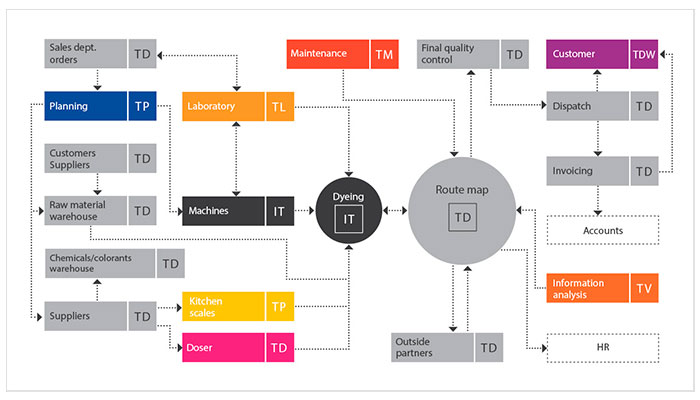

At EAS we have developed TexDrive: a software specially designed for the textile industry that allows a full integration with the plant. This is a modular system capable to be adapted to every process. It tracks the whole process from the moment the raw material enters the warehouse, manages the production orders and the complete routing. Also, our software can manage the commercial information from the beginning until the order is delivered.

Other outstanding functionalities included are label printing, stock and warehouse control, planning, cost control and external collaborators.

InfoTint: A software for the total control of textile production

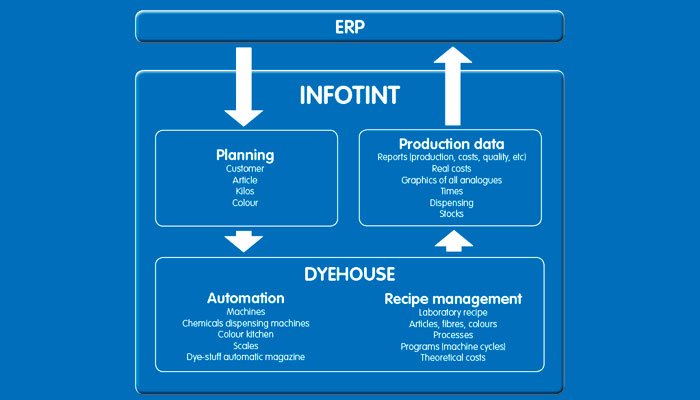

Among all the modules, InfoTint is the leading one. This system is designed to provide total control of the dry cleaner’s operation, managing the recipe integrally (processes and cycles). InfoTint uses a multi-user system which you can control the dye-house production, edit the dyeing cycles, recipes and processes. Also you can create and manage your own recipes and processes based on production formulas, calculate batches, create a planning and obtain statistics for later analysis.

The main advantage of Infotint is it’s capability to connect to the largest number of machines available on the market. It is flexible and customizable as more than 100 events can be configured. These features eliminate the mechanical work involved to make calculations of each new trichrome and introduces new data to ease changes in rules and parameters already established.

Other modular software

TexMonitor to control textile machines

TexDrive allows the integration of specific modules such as TexMonitor that collects all the information from each machine to display it on a monitor, to have the machine controlled at a glance. Data such as production analysis and status, machine downtime registration, visualization of complete OEE efficiencies per shift, operator and machine groups as well as downtime and alarm management are displayed and can be monitored all the time.

TexPlani for the control of textile production

Our planning module TexPlani allows to have the production controlled. When the order is generated, goes to a queue where a theoretical time for each batch is assigned and is placed in a timeline. All the orders can be sorted with a simple click to easily adapt them to the production.

TexMant maintenance, parts and inventory control

The TexMant module is designed for maintenance, enabling you to keep track of parts and inventory. This software can accurately record, keep and plan a control of the maintenance tasks. EAS commitment is to adapt your plant to 4.0 technology in order to control the whole process. By equipping your company with software and automating the machines you will see how the plant productivity reaches the next level to compete in the sector.

From EAS we always support you in this process being at your side. We can advise and provide demonstrations to show you how our software works and guide you through the whole process to adapt and customize your plant. Do not hesitate to write to us.