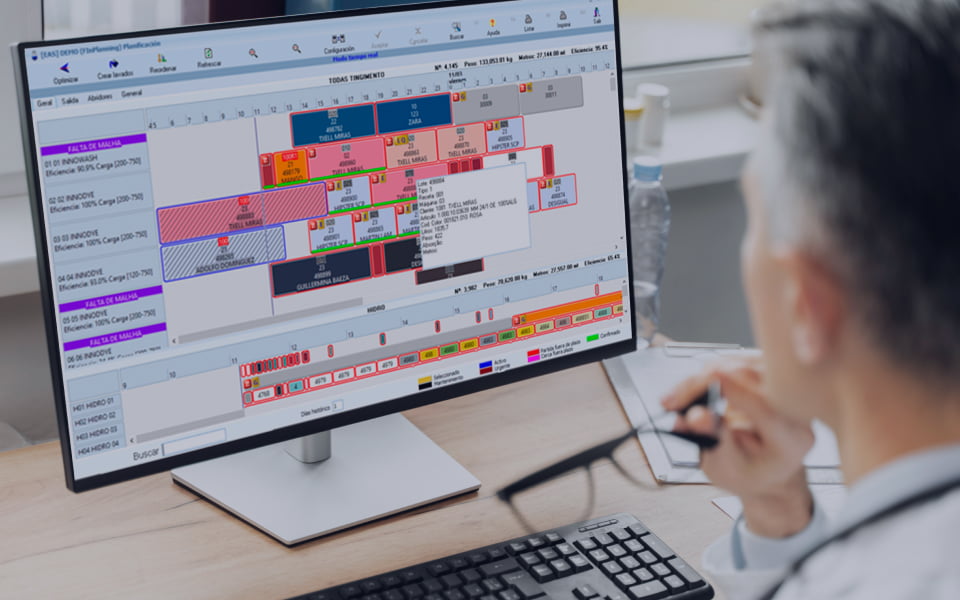

Solutions for dyeing and textile finishing process automation.

We have created a combination of our solutions to automate a textile dyeing and finishing sections. No matter the types of dyeing or company; all our solutions are adaptable and customizable. Join Industry 4.0