MES software designed for textile factory production management.

InfoTint guarantees complete traceability of the production process thanks to its seamless integration with ERP systems and automated weaving, dyeing, printing and finishing machines.

Manage your textile plant efficiently with InfoTint

MES software designed for textile factory production management.

InfoTint guarantees complete traceability of the production process thanks to its seamless integration with ERP systems and automated weaving, dyeing, printing and finishing machines.

MES software for production management in textile companies

InfoTint guarantees complete traceability of the production process thanks to its seamless integration with ERP systems and automated weaving, dyeing, printing and finishing machines.

Optimize processes, reduce tasks… gain efficiency, reduce costs and gain competitiveness. Give your growing company a new impetus for success. Give your growing company a new impetus for success.

Why InfoTint?

This software helps reduce labor time and facilitates the implementation of new developments by applying machine-specific rules.

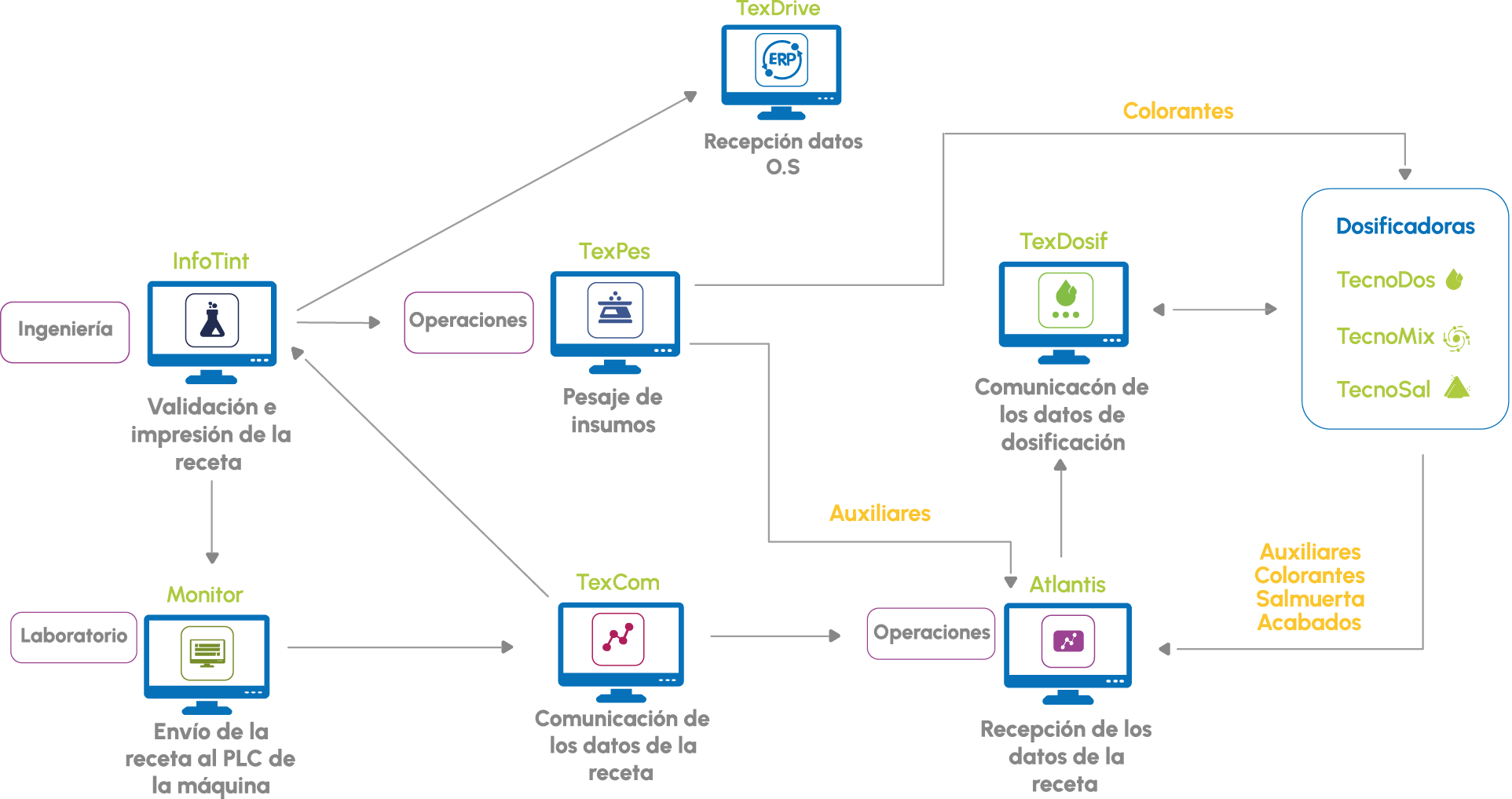

InfoTint enables a communication system that involves every part of the process, managing information in an efficient and traceable way.

Functionalities

InfoTint is a MES (Manufacturing Execution System) software designed to have total control of textile production processes. It centralizes the management and standardization of processes and recipes, implementing an agile production system that communicates with the machine park.

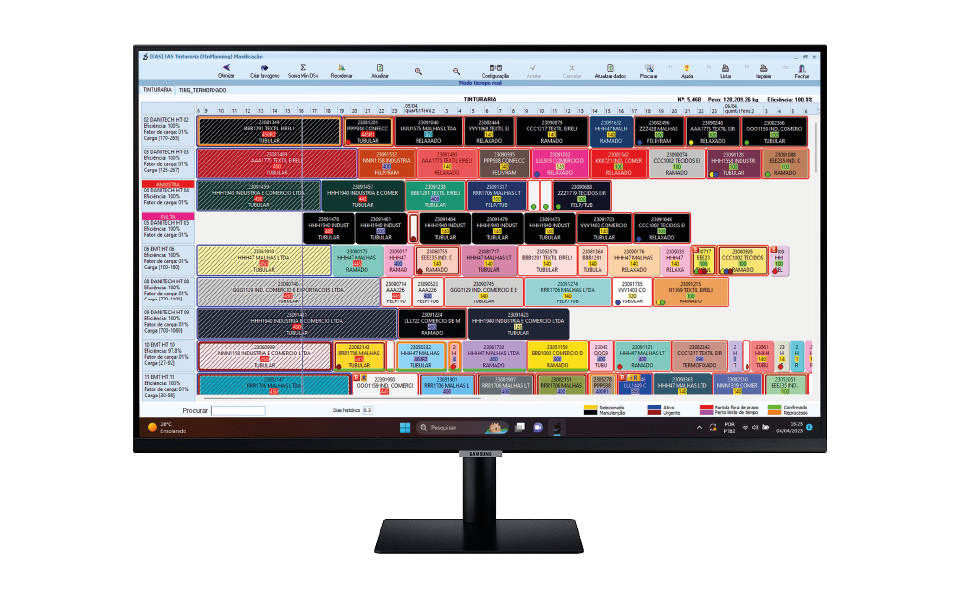

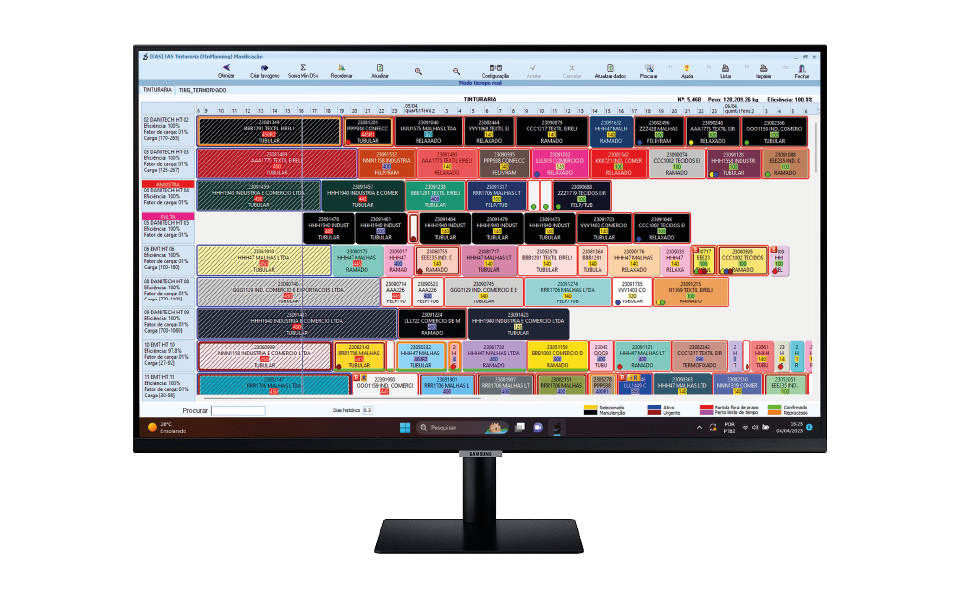

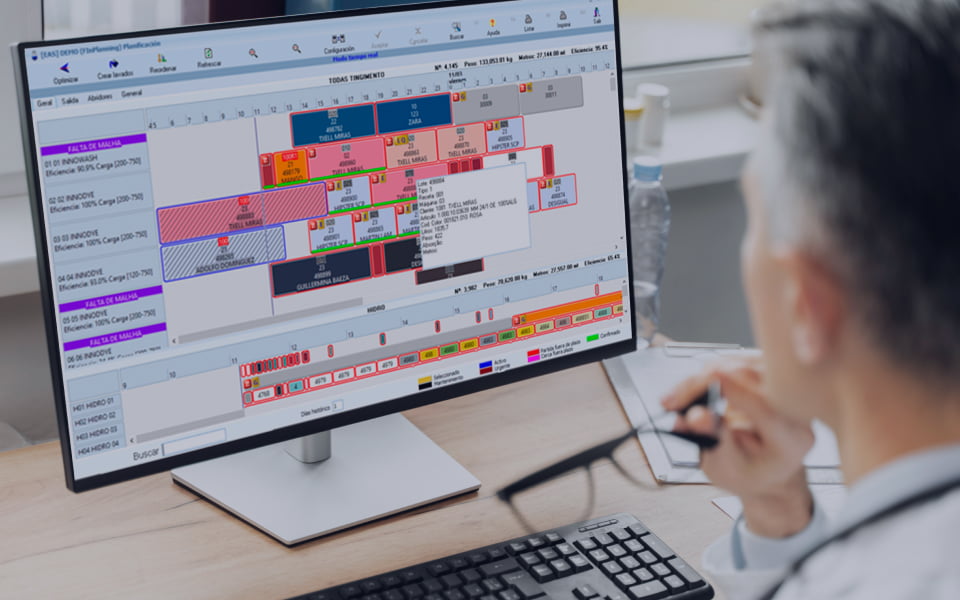

With our innovative integrated visual planner, you will have the ability to accurately track the incoming and outgoing flow of each batch in production. This tool enables you to optimize your production processes, minimizing downtime and maximizing your plant’s efficiency. Take advantage of this advanced solution to optimally manage your production!

What else InfoTint can do for your business

InfoTint as a MES (Manufacturing Execution System) program is designed to cover all the needs of textile manufacturing processes, it also allows you:

MES Modules

It is designed to connect with other software modules that allow you to expand and take full advantage of its potential.

Centralization of recipes and formulas

With InfoTint, you can easily digitize formulas and recipes for the various dyeing and finishing processes without having to enter data manually. All recipes are stored in a single environment, featuring an easy-to-use formula editor. You will be able to perform automatic calculations, considering any process variable, such as fiber type, product, or dyestuff, among others. InfoTint allows the following advantages