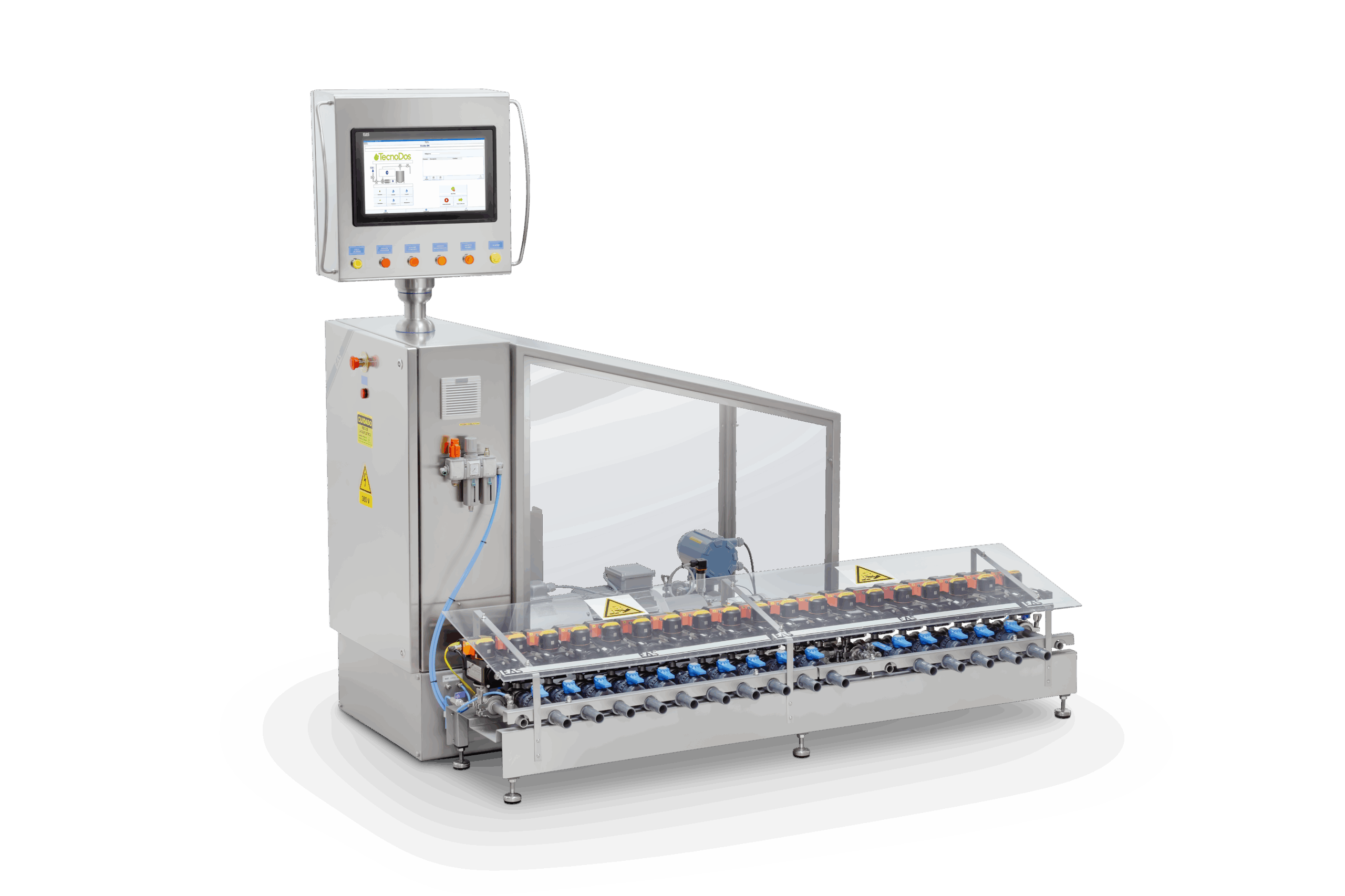

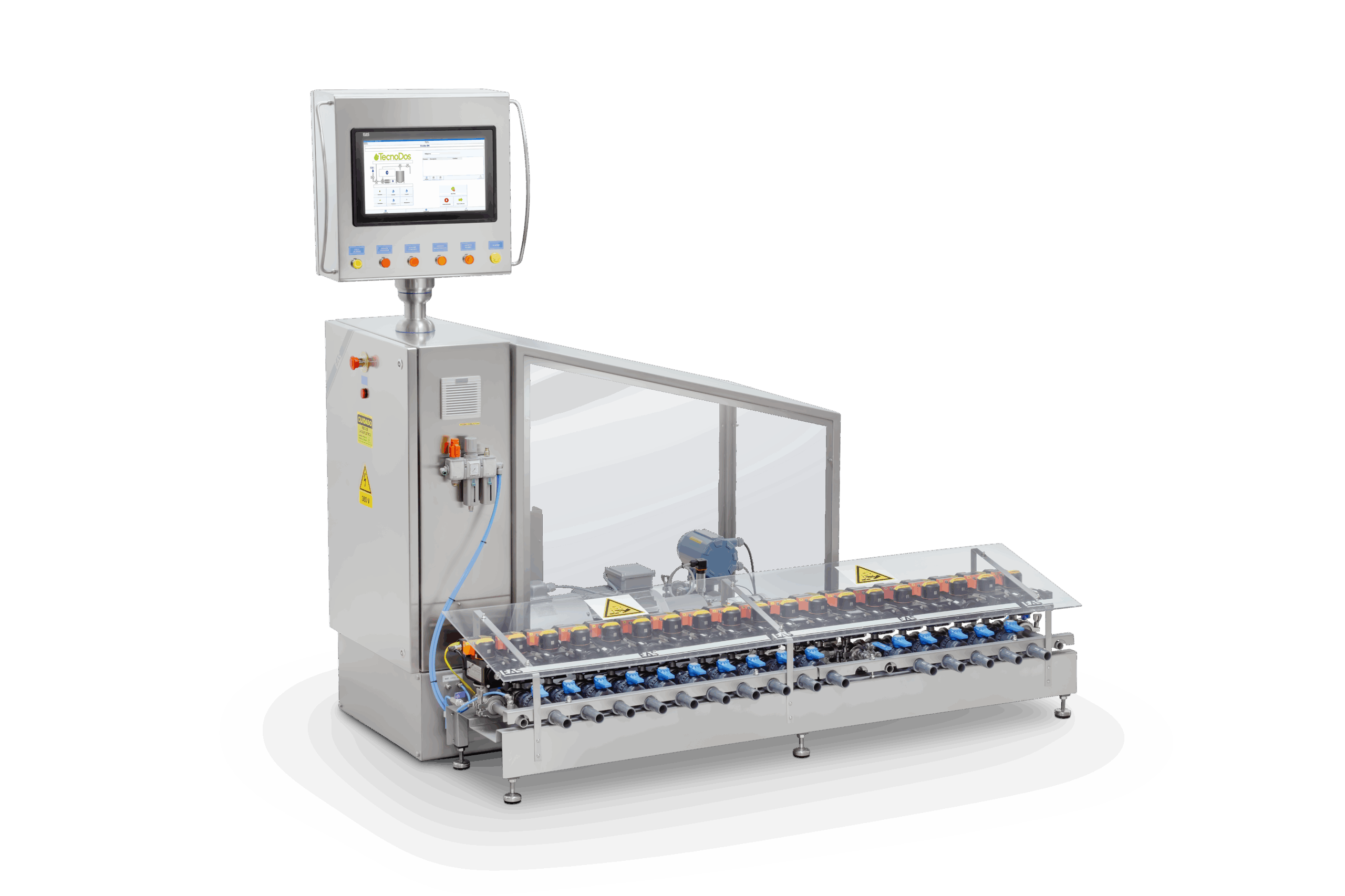

Precise dosing system for dyeing and finishing machines

TecnoDos is the dosing system for chemicals and liquid auxiliaries for dyeing machines such as jets, jiggers, industrial autoclaves, preparation and finishing machines.

Innovation in dosing for dyeing and finishing machines

Precise dosing system for dyeing and finishing machines

TecnoDos is the dosing system for chemicals and liquid auxiliaries for dyeing machines such as jets, jiggers, industrial autoclaves, preparation and finishing machines.

TecnoDos delivers the chemicals and liquid auxiliaries through its trilobular pump to a flow meter that meters the exact amount of product required by the recipe.

A monotube system is used to channel the products to the various tanks of the dyeing machines.

Once the dosing has been completed, it automatically manages an automatic line flushing and is ready for a new dosing. Thanks to its high-quality manifold, TecnoDos supports a wide range of chemicals.

Why TecnoDos?

TecnoDos, the dosing system that will help you work more efficiently than ever before and grow your business.

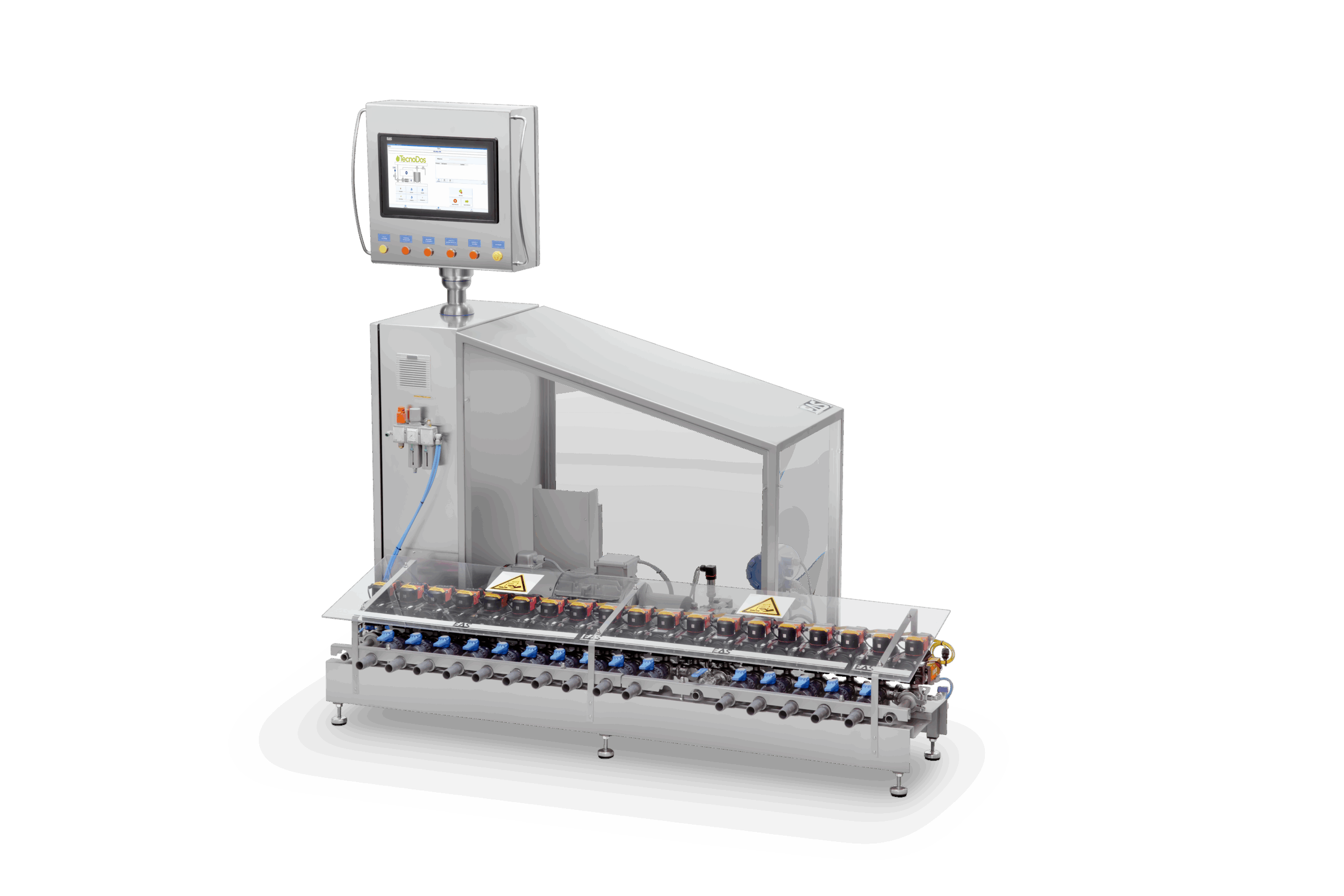

TecnoDos allows to automate Pad-Batch dosing system. This system allows the precise control of the 4:1 dosage in foulards. With this automation you will be able to manage the dosing of dyes, colourants and alcali, allowing to obtain the real pick-up of the article from the control of the level and speed of the fabric.

TecnoDos features our industrial controller Atlantis PCT-900. Its 15-inch design offers a large screen that allows you to control the entire process and connect other machines such as TecnoFill or TecnoMix. In addition, it integrates with our ERP Software TexDrive for and InfoTint with which you can control the entire textile production.

Reliability guaranteed

We have put our more than 30 years of industry experience to design durable, high-performance products. Además, con nuestro servicio técnico de asistencia en remoto te ayudaremos siempre que necesites.