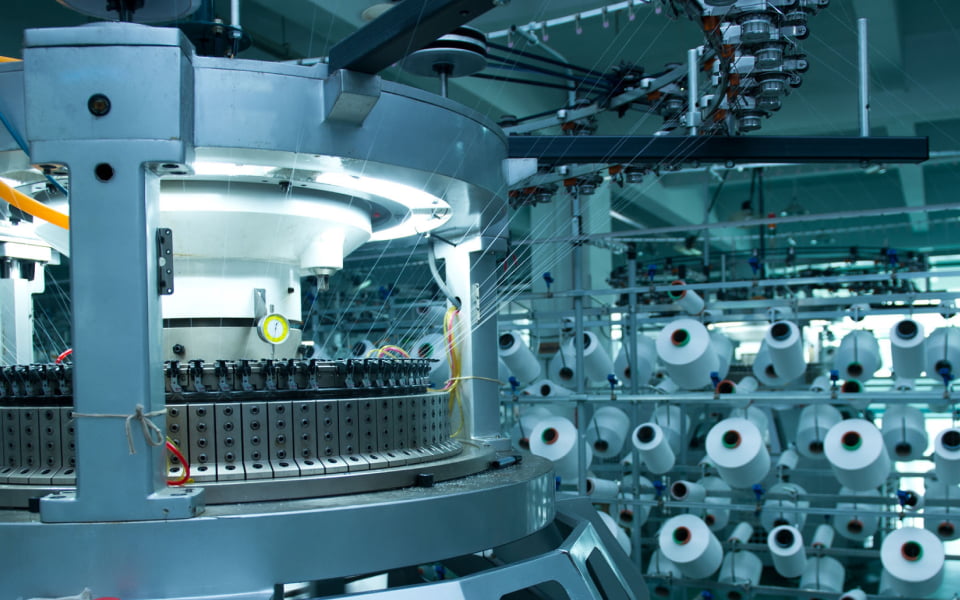

Automation solutions for weaving and knitting mills.

This is now a reality. The powerful combination of TexDrive, InfoTint and our Atlantis PCT-300 Stand Alone equipment enables a total control of production from start to finish, regardless of the type of fabric.